Exploring Eco-Friendly Materials in Car Manufacturing

The automotive industry has changed a lot in recent years. This change stems from more awareness of environmental sustainability. There is also an urgent need to reduce carbon emissions. Car manufacturers are now finding new ways to use eco-friendly materials in their production. This change meets the rising demand for greener vehicles. It also supports global efforts to fight climate change. In this blog, we’ll explore sustainable car materials. We’ll look at their benefits, uses, and the future of eco-friendly car production.

Why Sustainable Car Materials Matter

The importance of sustainable car materials cannot be overstated. The automotive sector is growing, but traditional manufacturing hurts the environment. Traditional materials like steel and plastic use a lot of resources. They also cause major pollution and greenhouse gas emissions. Sustainable materials are a better choice. They help the environment by cutting down on carbon emissions and saving important resources.

Moreover, the use of green vehicle components can enhance a car’s overall performance and longevity. Lightweight materials boost fuel efficiency. Durable, eco-friendly options also help vehicles last longer. These factors help the environment and also boost the economy for manufacturers and consumers.

Key Benefits of Eco-Friendly Automotive Production

Eco-friendly car production has many benefits. It helps the environment and the industry, too. Here are some of the key advantages:

Reduced Environmental Impact

By incorporating sustainable car materials, manufacturers can significantly reduce their environmental impact. Using recycled materials in car production can lower the need for new resources. This helps save energy and cut down on waste. Biodegradable materials also help reduce pollution. They break down naturally over time.

Enhanced Fuel Efficiency

Lightweight materials like aluminium and carbon fibre are gaining popularity in the automotive industry. They help improve fuel efficiency. Lighter vehicles use these materials to boost aerodynamics. This cuts fuel use, lowers emissions, and saves money for drivers.

Improved Vehicle Performance

Sustainable materials often offer superior performance compared to traditional alternatives. Natural fibres like hemp and flax are strong and durable. They’re great for car interiors and exteriors. These materials boost a vehicle’s performance. They also make driving more comfortable and enjoyable.

Economic Benefits

Eco-friendly automotive production can also yield significant economic benefits. Manufacturers can cut costs and boost profits by using fewer resources and generating less waste. The rising demand for green vehicles opens new market opportunities. This helps companies grow their customer base and increase sales.

Innovative Eco-Friendly Materials in Car Manufacturing

Manufacturers are looking into new, sustainable car materials as demand increases. Here are some of the most promising eco-friendly materials currently being used in the automotive industry:

Recycled Plastics

Recycled plastics are becoming increasingly popular in car manufacturing. They offer a sustainable alternative to traditional petroleum-based plastics. Manufacturers can cut their use of fossil fuels by using recycled materials. This also helps lower their carbon footprint. Recycled plastics can be shaped into many forms and sizes. This makes them useful for many purposes, like interior parts and exterior panels.

Natural Fibres

Natural fibres like hemp, flax, and jute are becoming popular in the automotive industry. They offer a great strength-to-weight ratio and have environmental benefits. These fibres are reinforced composite materials. They offer a lightweight and durable option compared to traditional materials. Also, natural fibres break down easily. This makes them a green choice for car interiors and exteriors.

Bio-Based Polymers

Bio-based polymers come from renewable resources like corn, sugarcane, and soy. They provide a sustainable option compared to regular plastics. These materials work well for many uses. You can find them in interior trim, upholstery, and even structural parts. Bio-based polymers not only reduce the industry’s reliance on fossil fuels but also contribute to a lower carbon footprint.

Aluminium and Magnesium Alloys

Aluminium and magnesium alloys are now common in car manufacturing. Their light weight and ability to be recycled make them a great choice. These materials can significantly reduce a vehicle’s weight, improving fuel efficiency and performance. Aluminium and magnesium alloys can be recycled forever. This makes them a great choice for sustainable car production.

Bamboo

Bamboo is an emerging material in the automotive industry, known for its rapid growth and sustainability. This versatile plant can make interior parts like dashboard panels and seat frames. It is a lightweight, durable, and eco-friendly choice compared to traditional materials. Furthermore, bamboo is biodegradable, making it an environmentally friendly option for car interiors.

Common Mistakes in Eco-Friendly Automotive Production

The move to sustainable car materials is great, but manufacturers can make mistakes. Here are some to watch out for:

Overlooking the Entire Lifecycle

To evaluate a material’s sustainability, consider its whole lifecycle. This includes everything from production to disposal. Only looking at a material’s environmental benefits while it’s used can cause problems. For example, it might lead to more energy use or waste when making or disposing of it. Manufacturers should take a holistic view. They need to think about how a material affects the environment at every stage of its life.

Neglecting Performance and Safety

Sustainability is a crucial consideration. It’s essential not to compromise on performance and safety. Manufacturers must make sure eco-friendly materials perform and are as safe as traditional ones. This way, consumers can enjoy a reliable and safe driving experience.

Failing to Communicate Benefits to Consumers

More people want to know about the environmental benefits of green vehicles as demand rises. Manufacturers need to clearly share the benefits of sustainable car materials. They should focus on their positive environmental impact, performance perks, and cost savings. This transparency can help build consumer trust and drive demand for eco-friendly vehicles.

Advanced Insights and Expert Recommendations

The automotive industry is always changing. To keep up, manufacturers need to adopt new materials and production methods. Here are some expert recommendations for advancing eco-friendly automotive production:

Invest in Research and Development

Investing in research and development is key to boosting innovation in sustainable car materials. Manufacturers can lead the industry by exploring new materials and production methods. This helps them meet the rising demand for eco-friendly vehicles.

Collaborate with Suppliers and Industry Partners

Collaboration is key to advancing eco-friendly automotive production. Manufacturers should team up with suppliers and industry partners. Together, they can create and use sustainable materials and practices. This partnership can spark innovation, cut costs, and speed up the use of green vehicle parts.

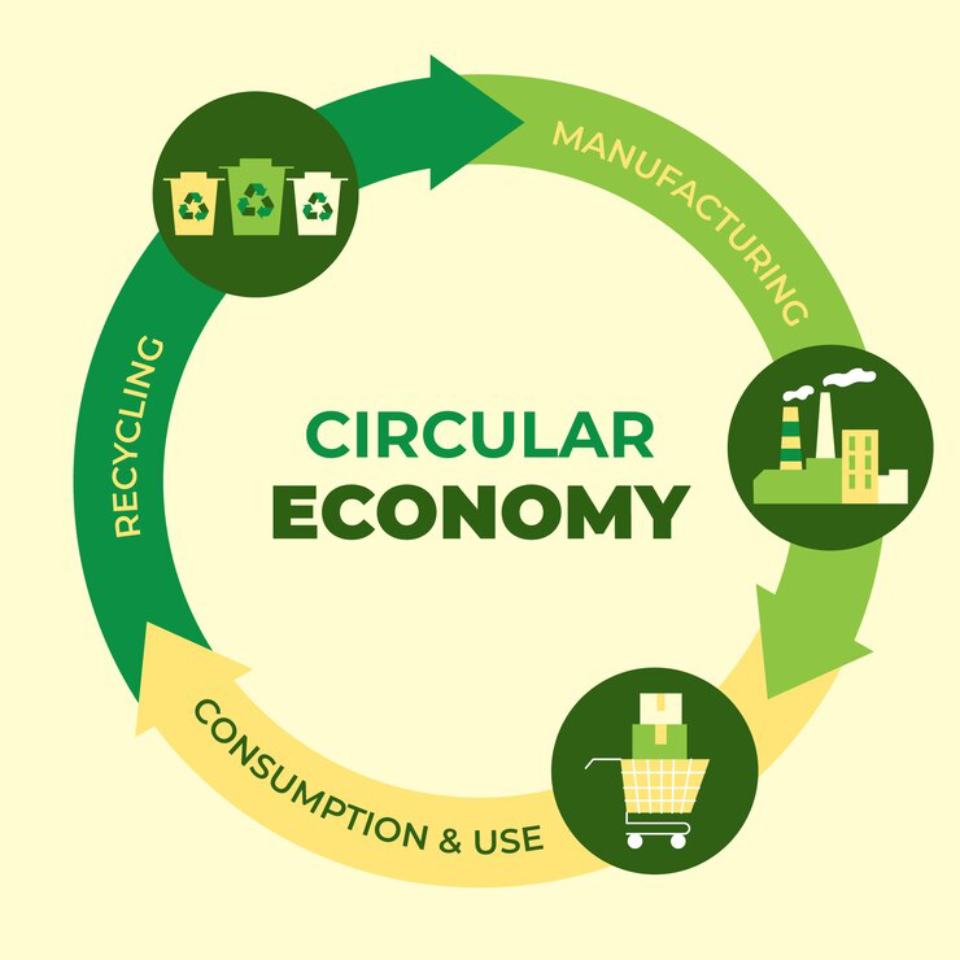

Embrace Circular Economy Principles

Adopting circular economy principles can help manufacturers minimise waste and maximise resource efficiency. Companies can reduce their environmental impact by designing recyclable products and reusing materials. This helps create a more sustainable automotive industry.

Conclusion: Driving the Future of Sustainable Automotive Materials

The automotive industry is changing. Using sustainable car materials will be key to its future. Eco-friendly car production helps manufacturers cut their environmental impact. It also boosts vehicle performance and meets the rising demand for green cars. Looking ahead, we must keep innovating and collaborating. This will help develop and adopt sustainable materials. Together, we can create a more sustainable automotive industry.

In conclusion, using eco-friendly materials in car manufacturing isn’t just a trend. It’s a vital move for a sustainable future. Manufacturers can create a greener, more sustainable automotive industry. They can do this by investing in research and development, working with industry partners, and embracing circular economy principles. We can help by supporting eco-friendly vehicles. This boosts demand for sustainable car materials and aids in creating a healthier planet.